Selecting the appropriate footwear manufacturing equipment is a crucial step in ensuring production efficiency and product quality. This article will introduce the factors to consider when choosing footwear manufacturing equipment, helping companies make better decisions that align with their needs.

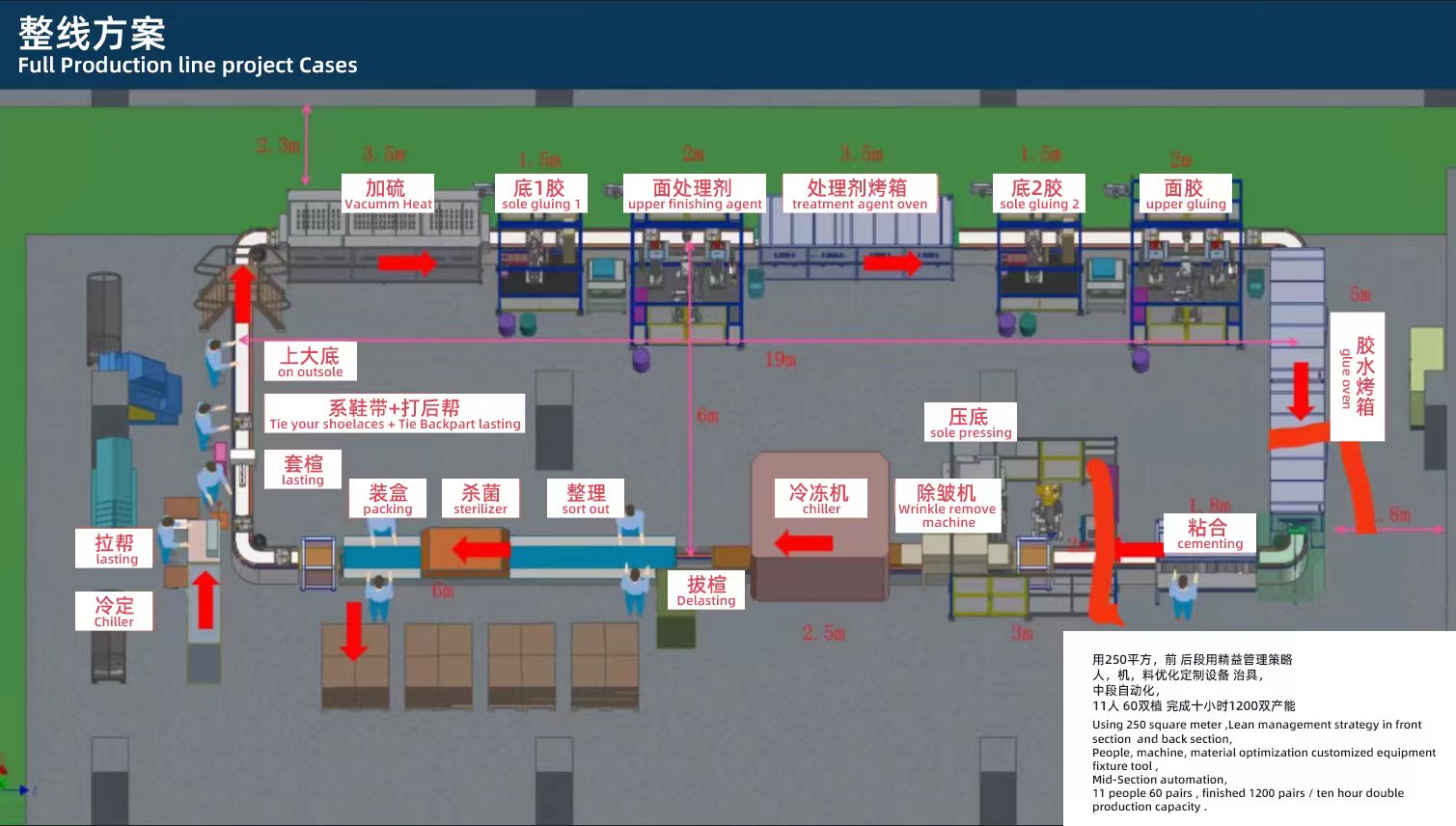

Understanding Company Production Requirements:

Analyze the company's production scale, product types, production processes, etc., to determine the types and quantities of footwear manufacturing equipment needed.

Based on the production scale, choose the appropriate equipment capacity and production line configuration to ensure meeting the company's production needs.

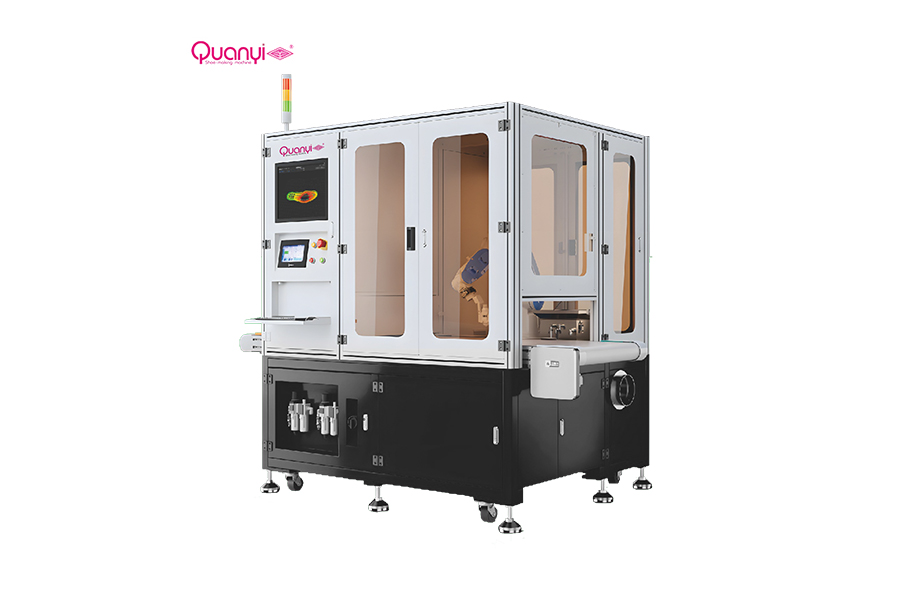

Consider Equipment Brand and Quality:

Choose equipment from reputable brands, focusing on quality and performance to ensure stable operation and long-term use.

Understand the reputation and user reviews of different brands, selecting suppliers with good reputation and reliable quality.

Comprehensively Evaluate Cost and Performance:

Besides equipment price, consider factors such as performance, maintenance costs, energy consumption, etc.

Make a comprehensive assessment of cost and performance to choose the most optimal equipment, ensuring a reasonable return on investment.

Understand After-Sales Service:

Select suppliers with comprehensive after-sales services, ensuring timely provision of equipment maintenance and spare parts replacement.

Understand the coverage, response time, and quality of after-sales services, choosing suppliers that can guarantee long-term stable operation of the equipment.

Consider Technological Updates and Upgrades:

Choose suppliers that can provide timely technological updates and equipment upgrade services to adapt to industry technological advancements and changing production needs.

Consider the scalability and upgradability of the equipment to ensure it can meet future production expansion and technological upgrade requirements.

By considering these factors, companies can better select footwear manufacturing equipment that aligns with their needs, ultimately improving production efficiency and product quality.

cs@quanyishoemachine.com

cs@quanyishoemachine.com 8618924530803

8618924530803

CHAT

CHAT MESSAGE

MESSAGE