In the footwear industry, having efficient factory equipment is crucial for improving production efficiency and ensuring product quality. This article will introduce the key role of footwear factory equipment and how to choose equipment that suits your company's needs.

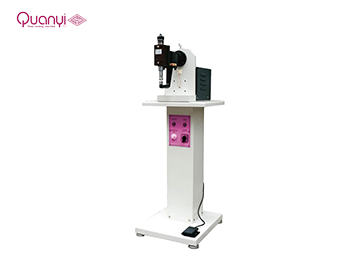

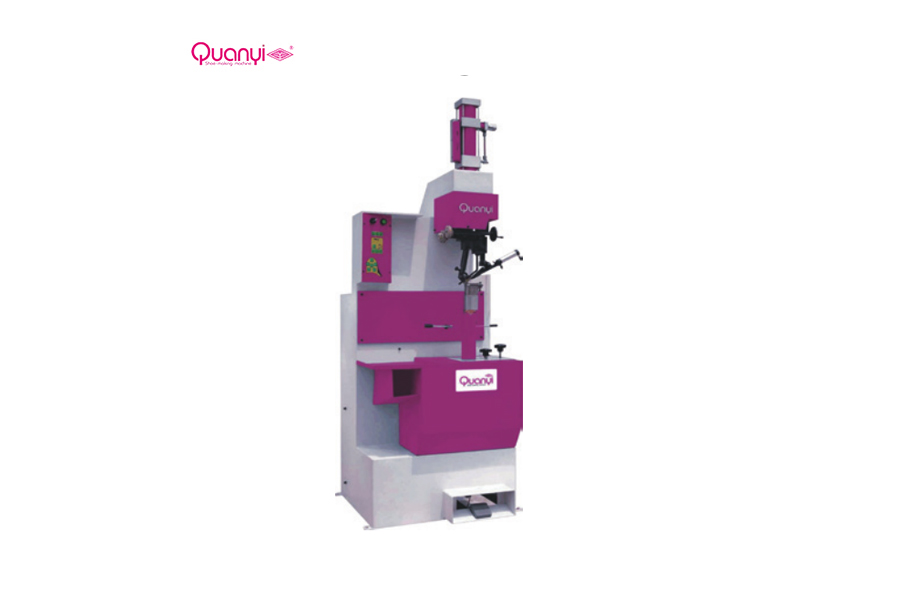

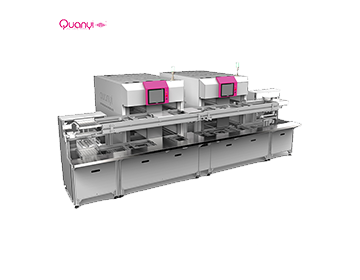

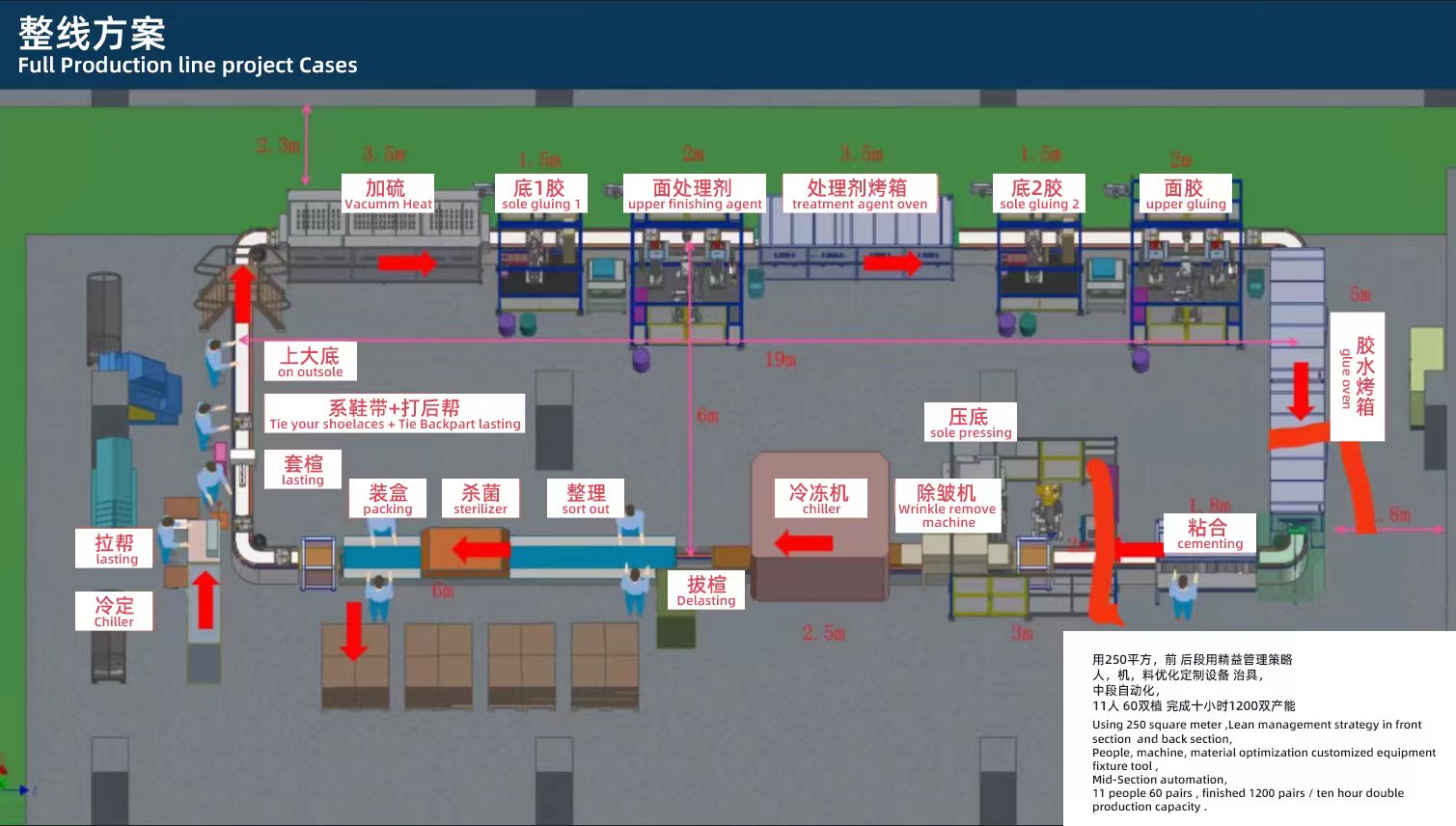

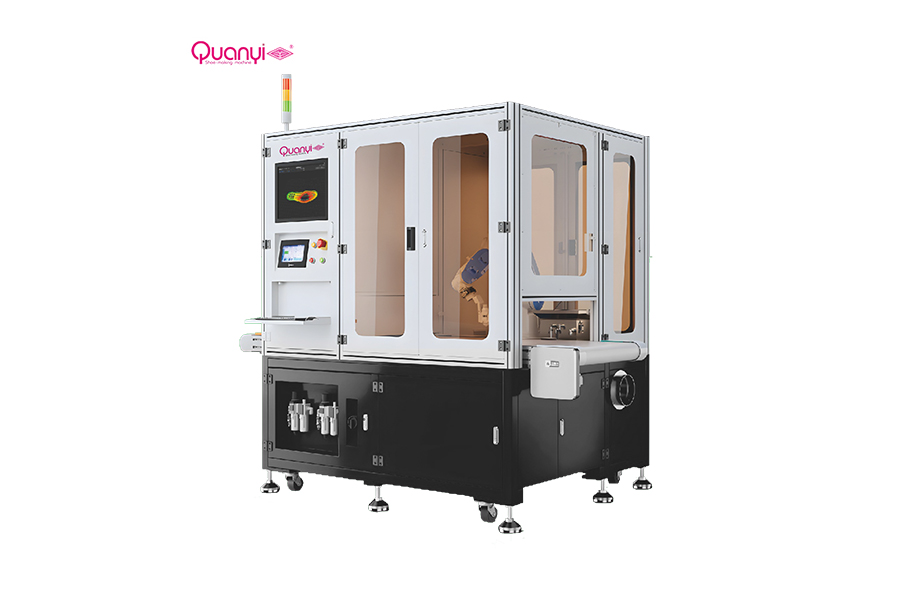

Types and functions of footwear factory equipment: From shoe upper design, sole manufacturing to shoe assembly, the footwear production process involves multiple stages. Different footwear equipment has different functions, such as sewing machines, sole press machines, toe-lasting machines, etc. Each type of equipment plays a crucial role in the footwear manufacturing process.

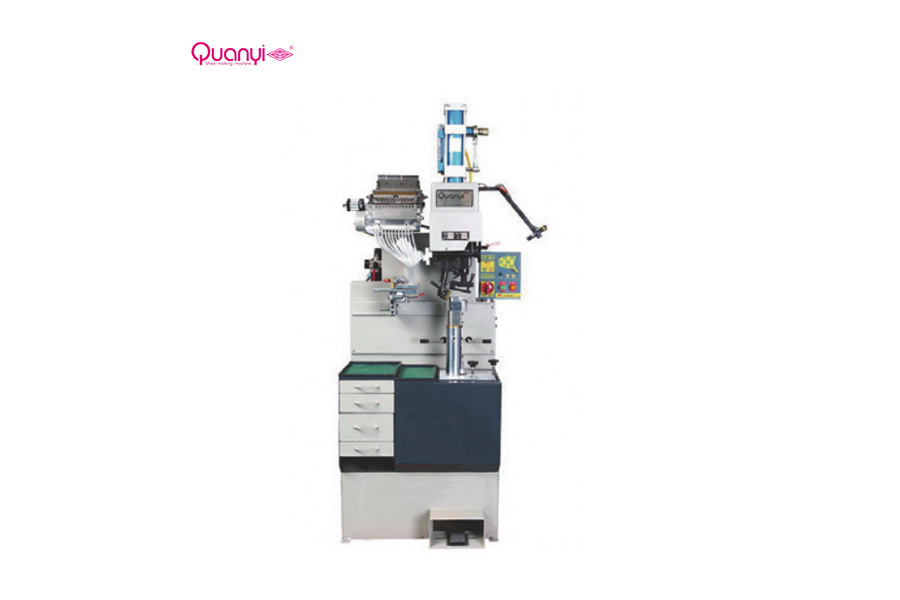

For example, sewing machine:

Function: Used to stitch various parts of the shoe upper (such as vamp, tongue, quarters) together to form the complete shoe structure.

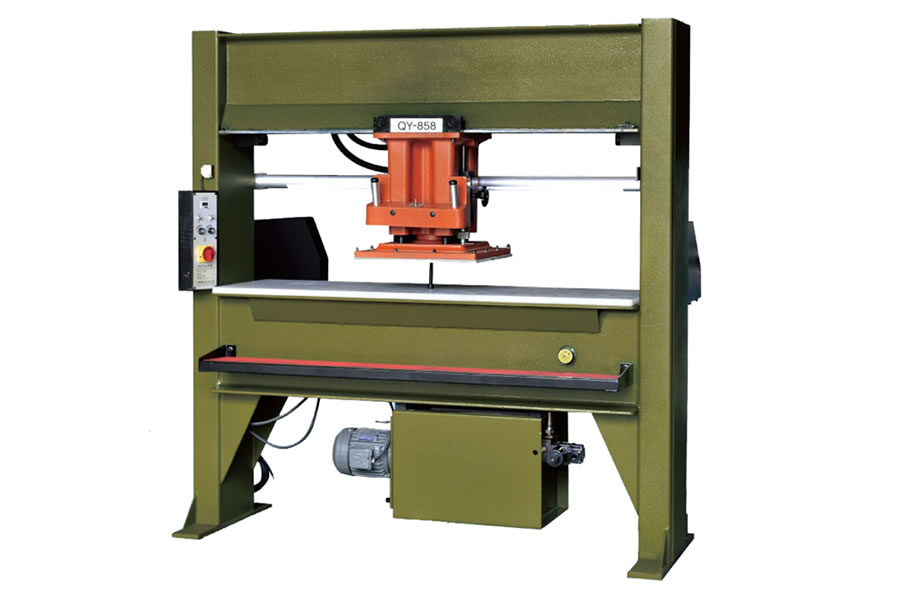

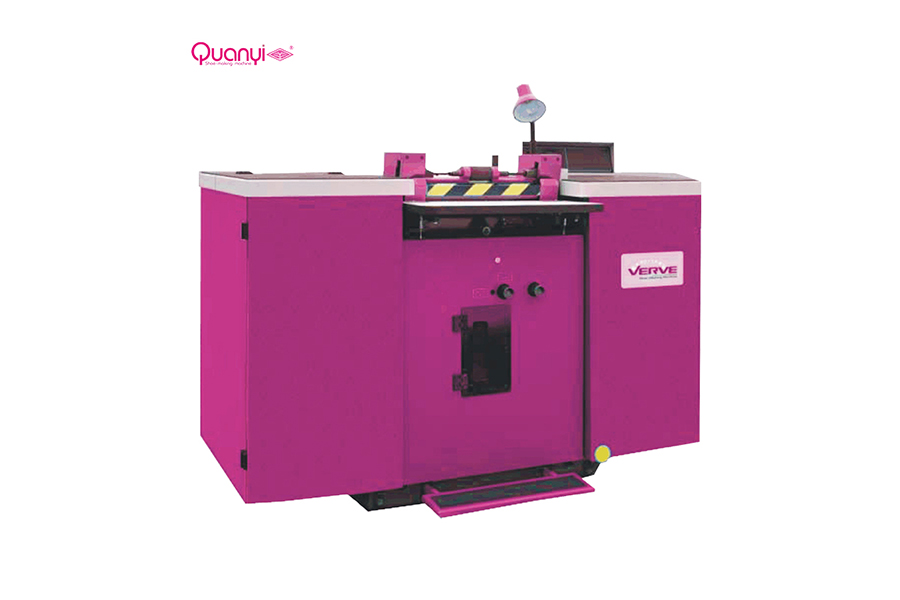

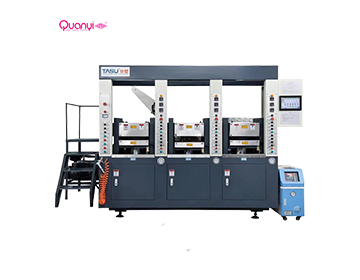

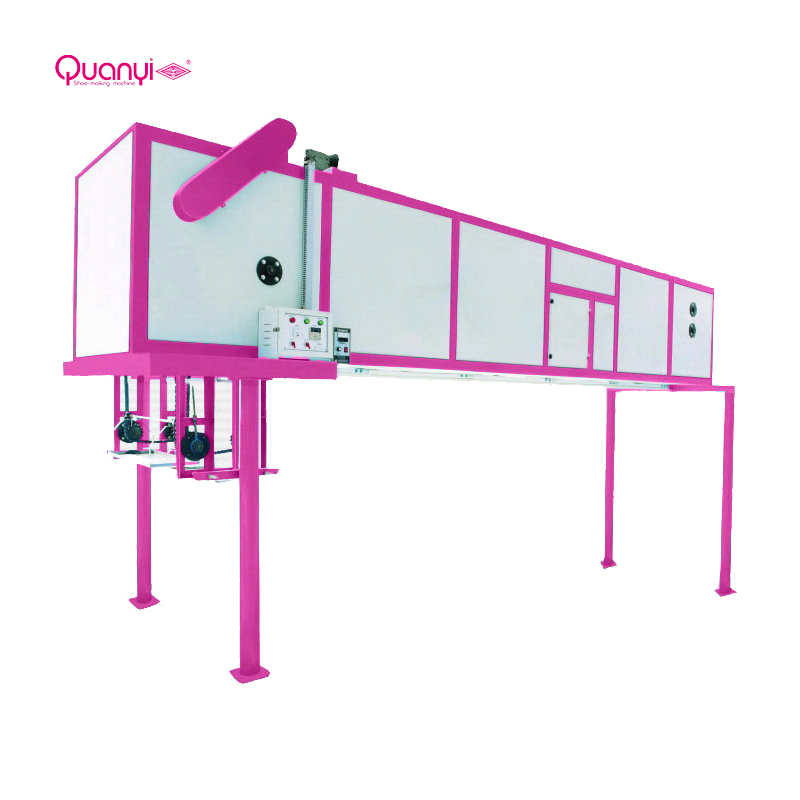

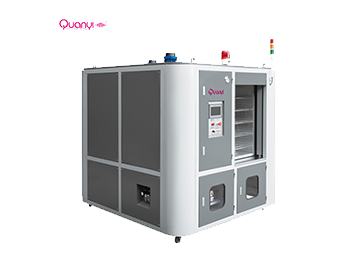

Sole press machine:

Function: Used to fix and bond the sole to the upper, ensuring the structural integrity and stability of the shoe.

Analyzing the impact of equipment on production efficiency: Efficient equipment can significantly reduce the production cycle, labor costs, and improve product quality and output, thereby enhancing the competitiveness of enterprises.

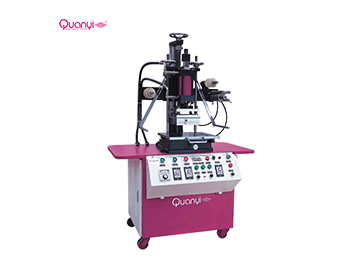

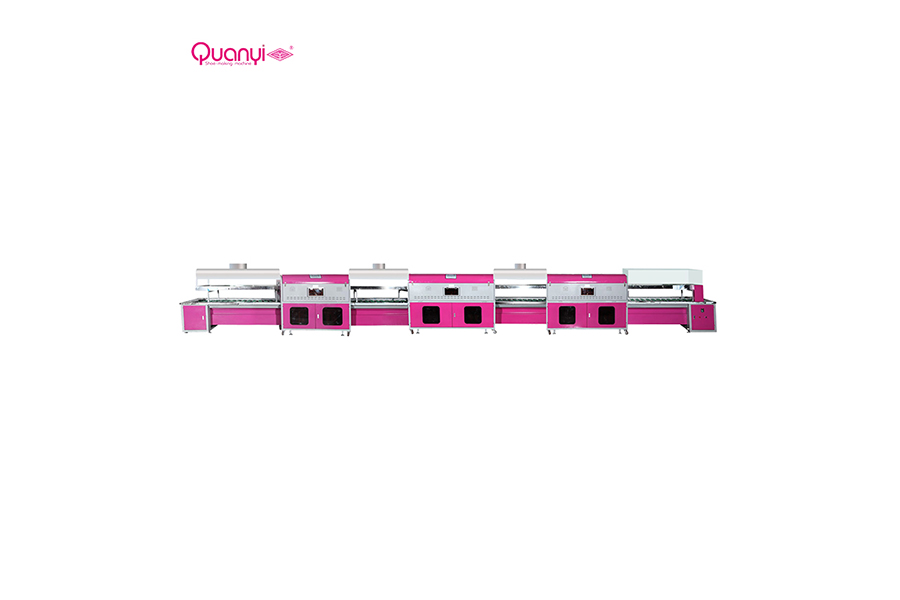

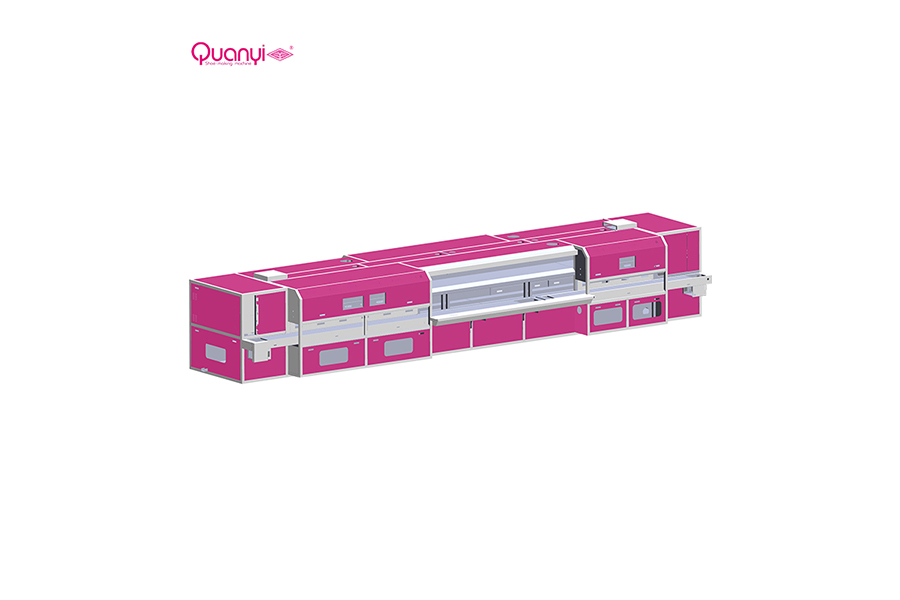

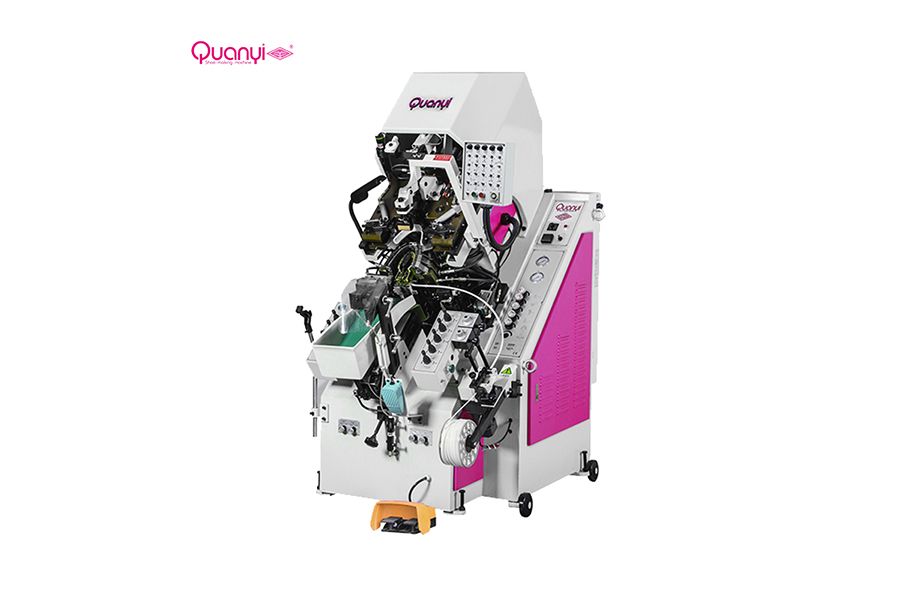

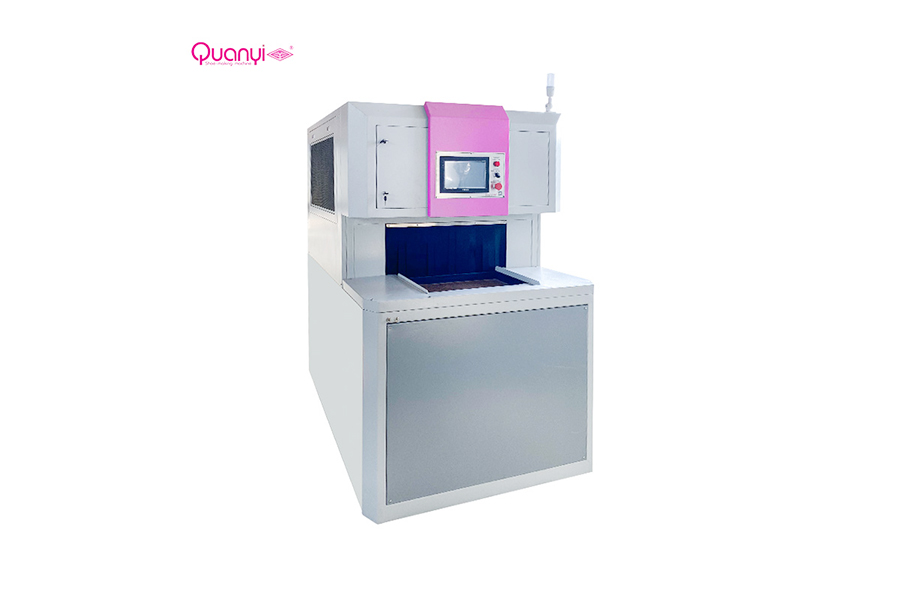

Toe-lasting machine:

Function: Used to attach the toe box (front part of the shoe upper) to the sole. This step is typically completed during the shoe assembly process to ensure the structural integrity of the shoe.

So, how to choose suitable footwear equipment? We need to consider factors such as production scale, budget, product types, etc. Choose equipment that suits your company's needs and pay attention to aspects such as equipment brand, quality, after-sales service, and the manufacturer's ability to update and upgrade equipment: The footwear industry is constantly evolving technologically. Timely updating and upgrading equipment are key to maintaining competitiveness. By understanding the latest technological trends in the industry and the update and upgrade situation of equipment, you can choose new equipment suitable for your company.

cs@quanyishoemachine.com

cs@quanyishoemachine.com 8618924530803

8618924530803

CHAT

CHAT MESSAGE

MESSAGE