Region:North America

Shoe shape:SAFETY SHOES

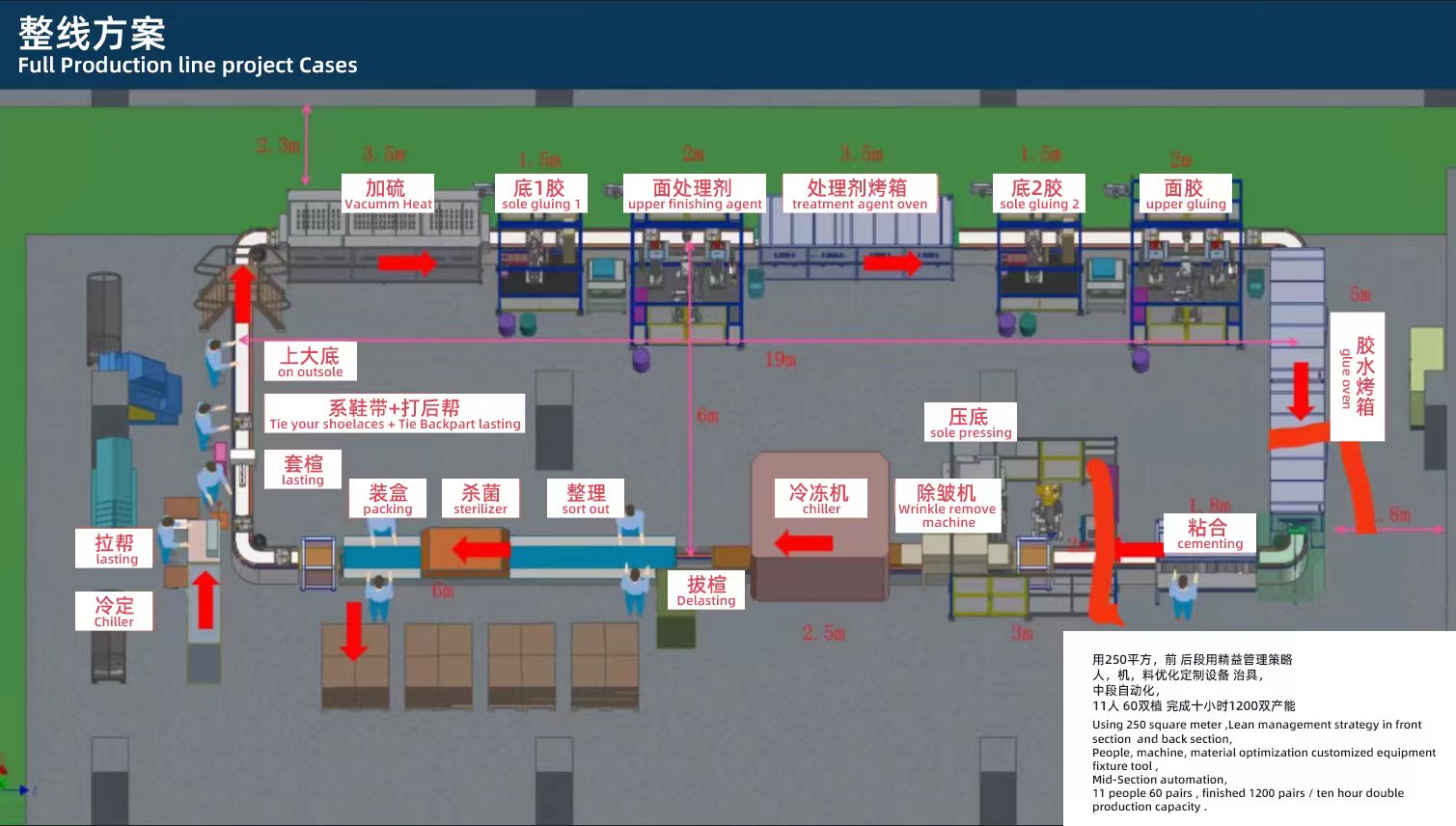

Assemble Space:100㎡

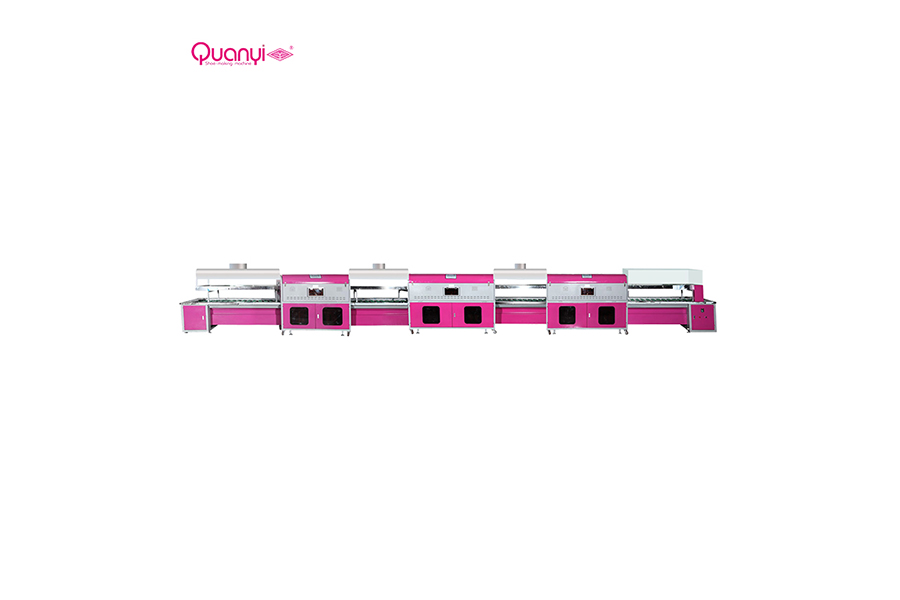

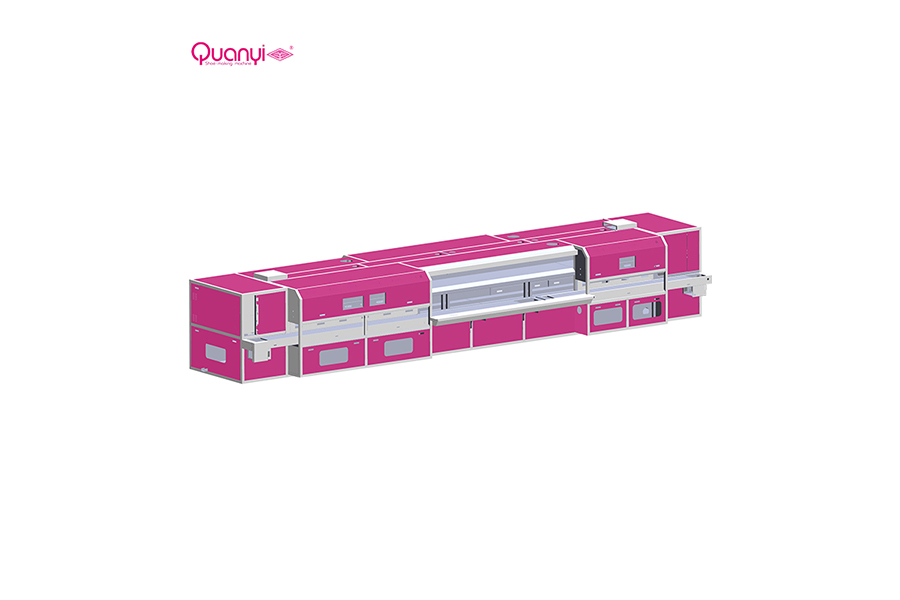

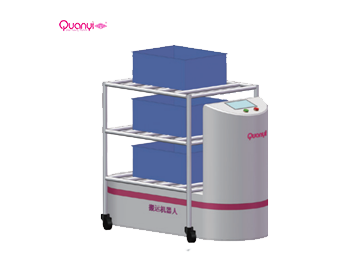

Process:The lean U-shaped layout in shoe manufacturing facilitates continuous production flow, shortens the production cycle, and allows for flexible adjustment of workforce and output for agile production. This layout, characterized by its compact size and multi-tasking by individual workers, promotes balanced production operations. It reduces inventory levels and accelerates capital turnover, eliminating the eight major wastes in production. This alleviates a company's financial, storage, and management pressures.

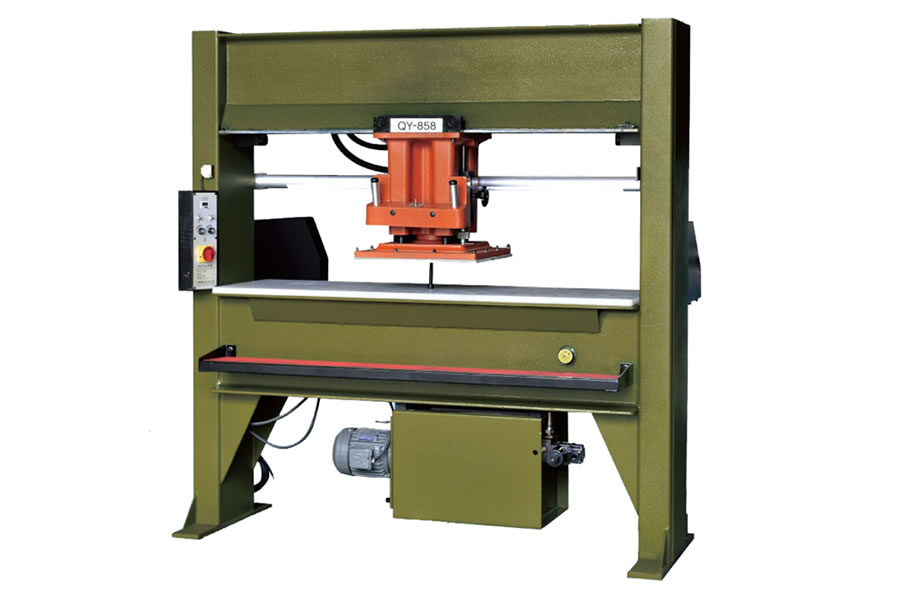

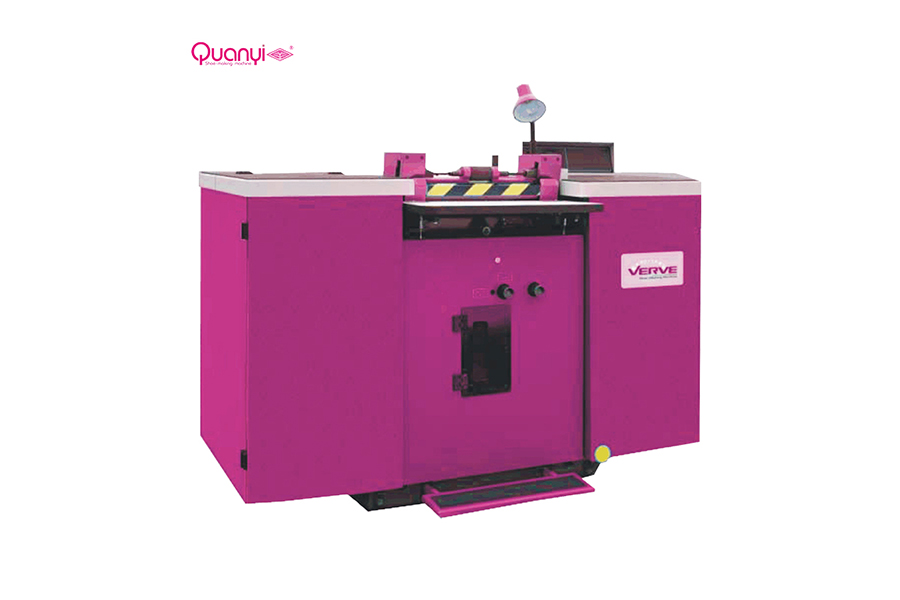

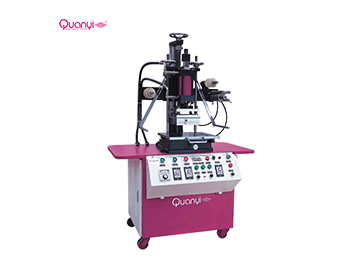

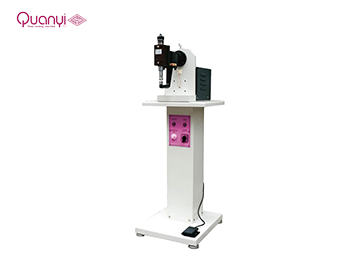

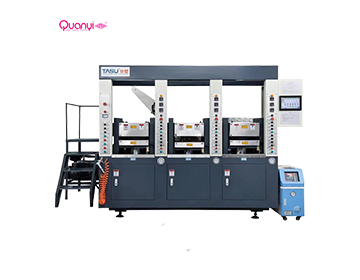

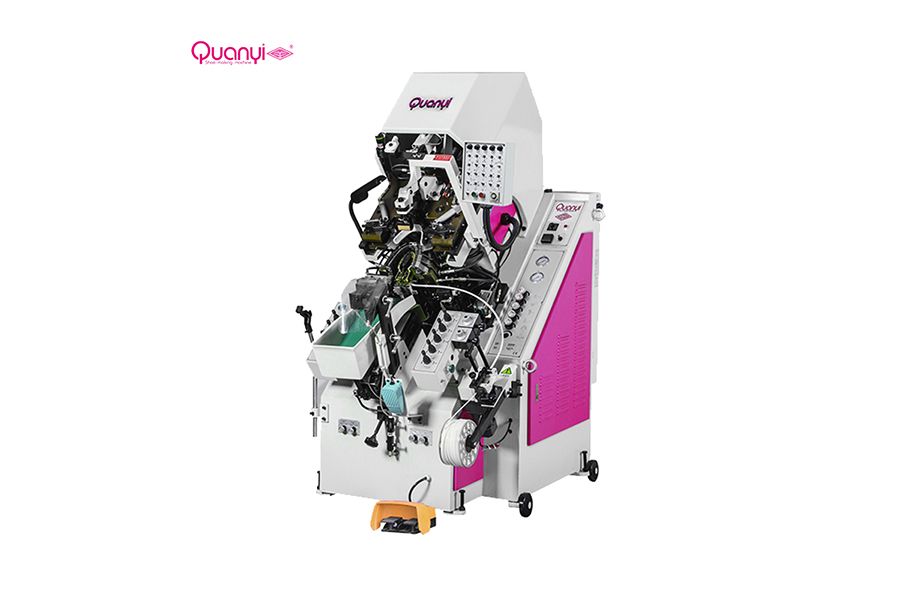

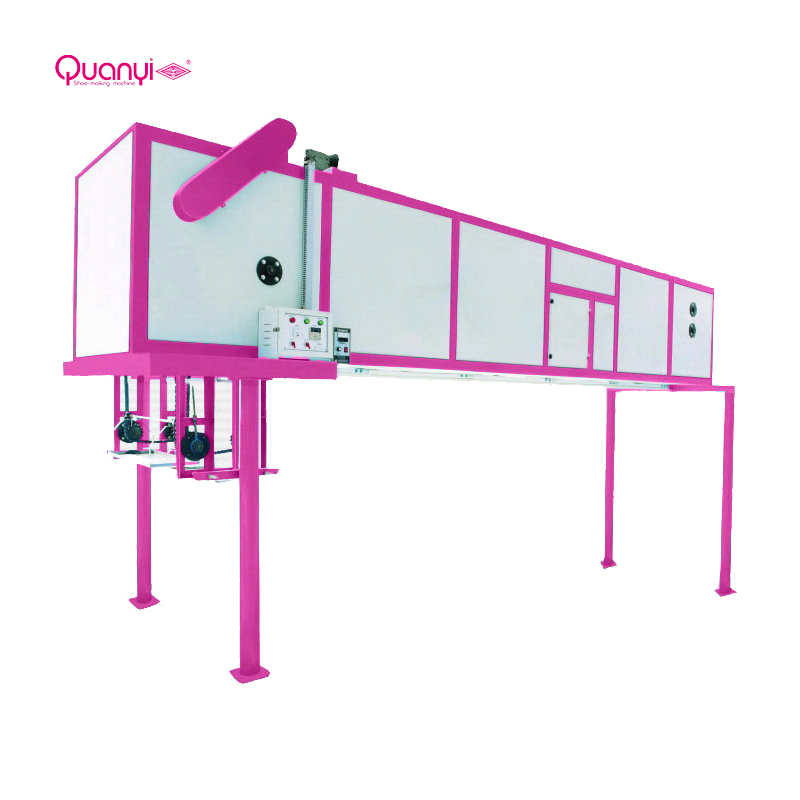

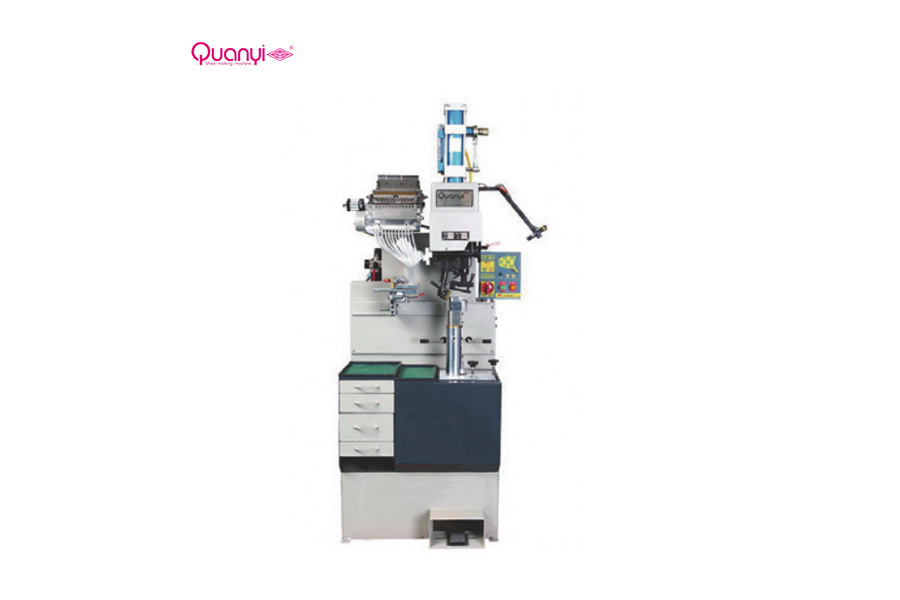

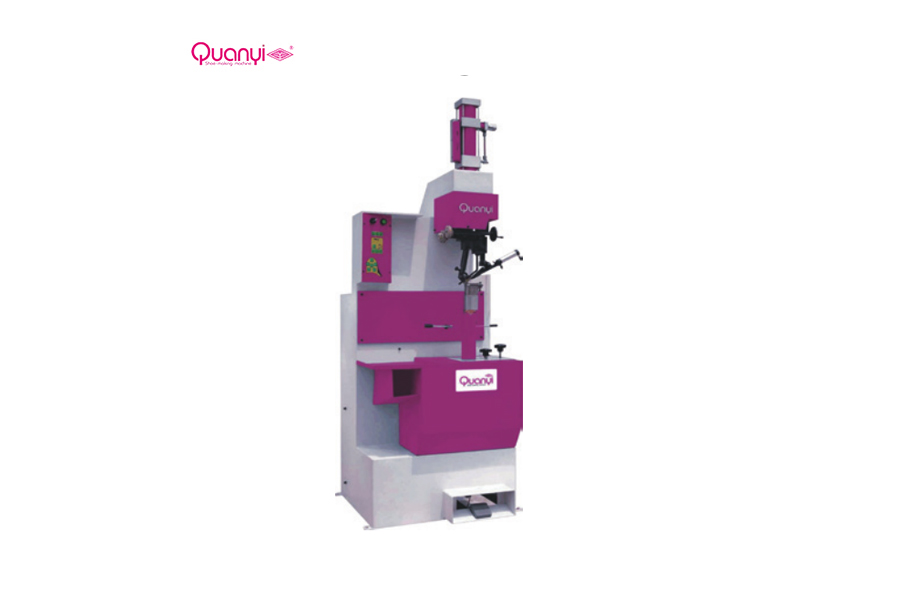

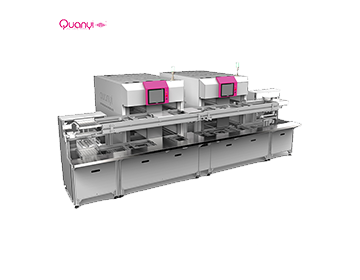

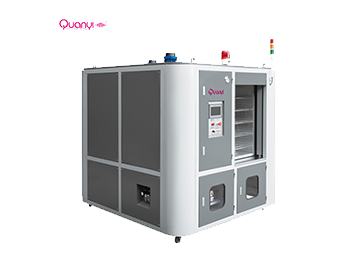

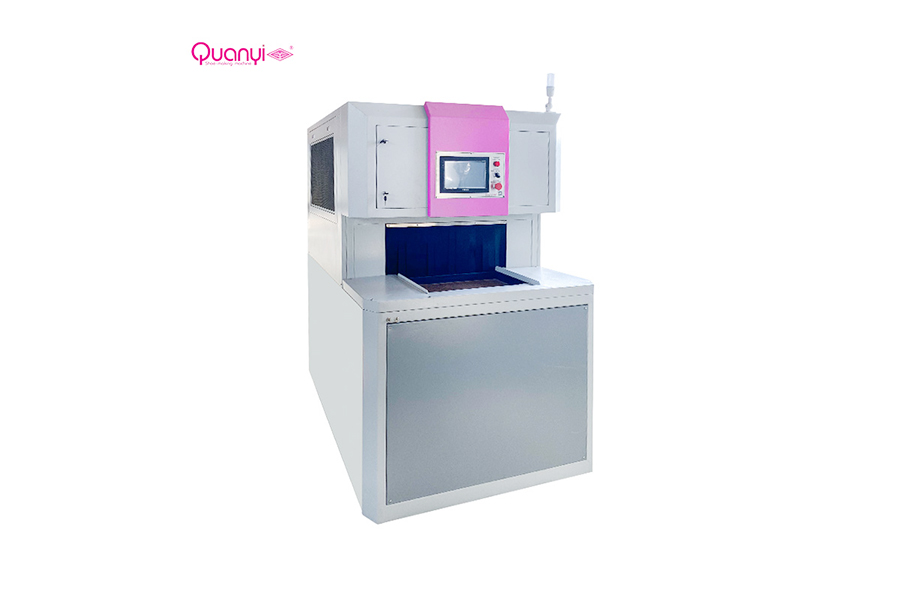

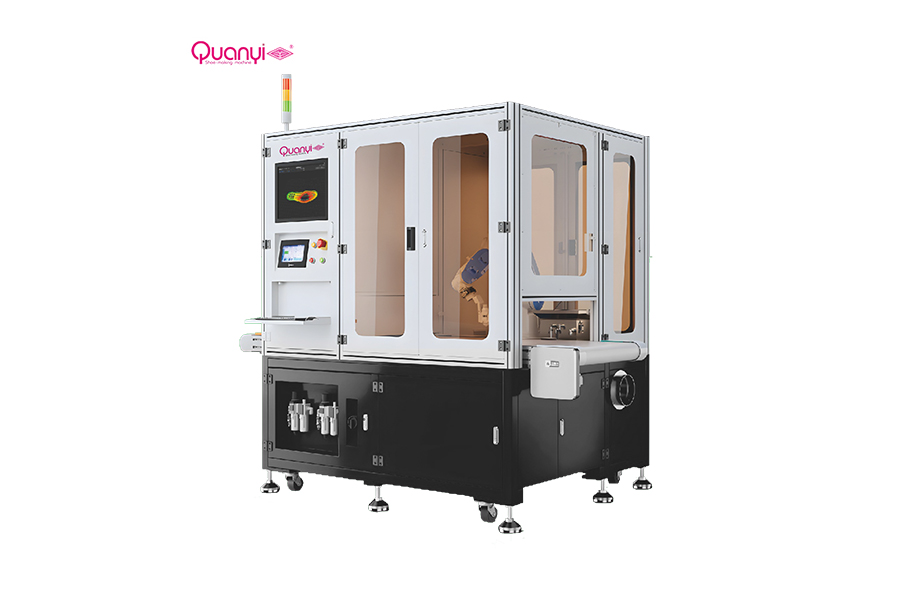

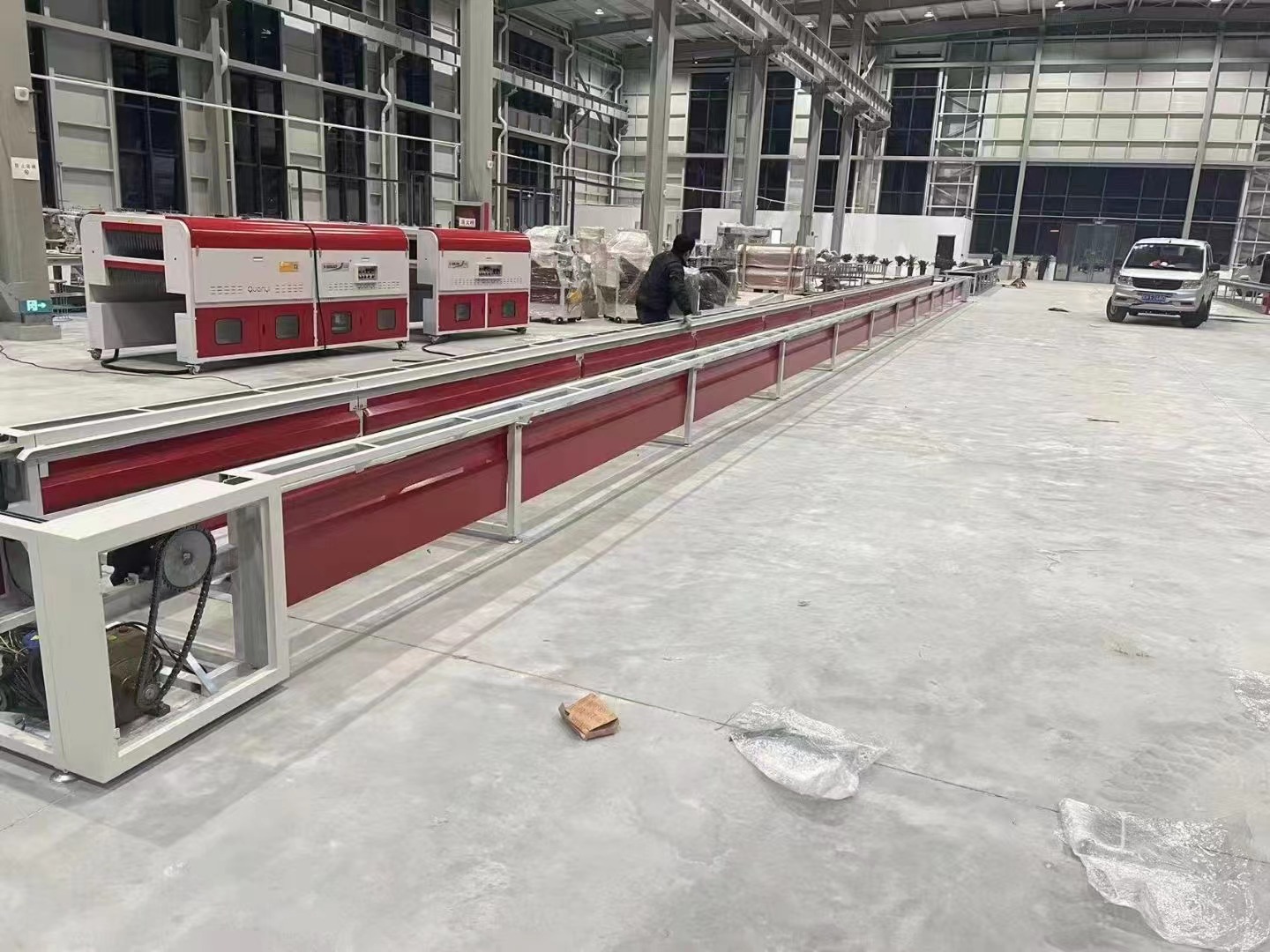

By establishing standards for lean shoe production layouts and incorporating automation, such as single-point automation that replaces manual labor with machines, significant improvements can be achieved with fewer people. Examples include automatic cutting machines, computerized pattern machines, automatic roughing machines, automatic gluing machines, automatic packaging, etc.

The integration of MES (Manufacturing Execution System) for digital management provides businesses with digital feedback on sales in the era of comprehensive internet development. This fully digital integration is particularly suited for future sales scenarios, where digital sales support each other's needs, achieving MAS (Manufacturing Automation Systems) big data management and entering a "dynamic order-replenish-iterate" mode.

cs@quanyishoemachine.com

cs@quanyishoemachine.com 8618924530803

8618924530803